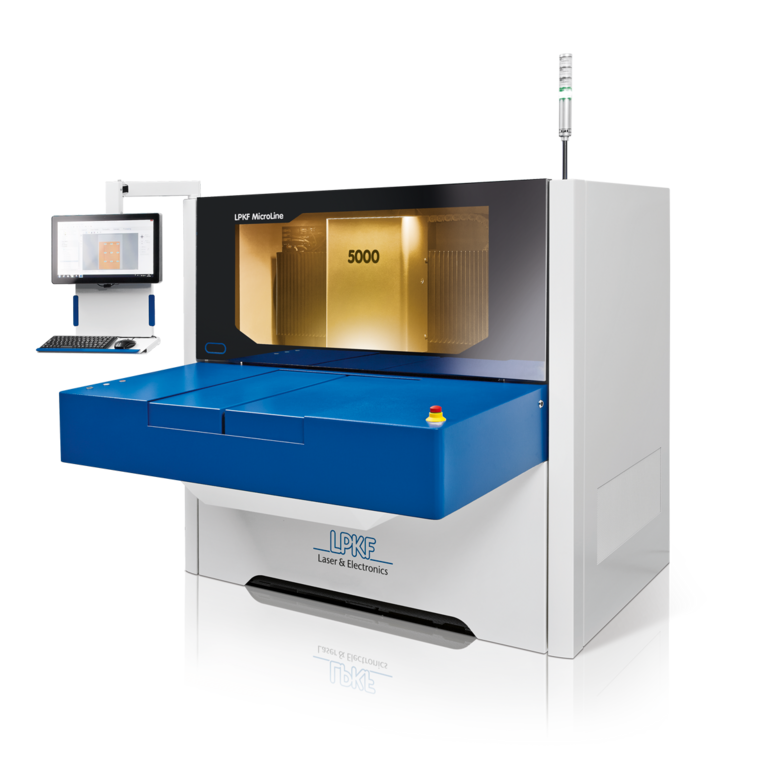

Quality and precision

The UV laser delivers a particularly high quality because it cuts and drills even sensitive materials with a minimal thermal stress zone. The result is impressive: clean edges, no dust, no burr. The MicroLine 5000 systems have powerful 10 W, 15 W and 27 W laser sources and can be configured for different material handling variants.

Contour cutting

The MicroLine 5000 is a universal tool. In addition to drilling, standard panel sizes up to 533 mm × 610 mm can be cut. With a cutting channel of only 20 μm, the high-quality UV laser is also suitable for cutting demanding contours at high speeds.

Process monitoring

An integrated vision system in the MicroLine 5000 systems ensures fast fiducial recognition and thus precise alignment. The camera can use virtually any PCB feature as a fiducial mark. An integrated power measurement determines the laser power at material level for reliable and repeatable control.

Technical data

| MicroLine 5000 | |

|---|---|

| Max. working area | 533 mm x 610 mm (21" x 24") |

| Positioning accuracy | +/- 20 µm |

| Diameter of focused laser beam | 20 µm |

| System dimensions (W x H x D) | 1660 mm x 1720 mm x 1900 mm (66" x 68" x 75")* |

| Weight | ca. 2000 kg |

* Height incl. status light = 2200 mm (87")

Available Variants

| Laser power | Wavelength | Pulse duration | 5000 series | CleanCut |

|---|---|---|---|---|

| 27 W | 355 nm (UV) | nano second | MicroLine 5127 | X |

| 40 W | 355 nm (UV) | pico second | PicoLine 5440 | X |