Why Laser Depaneling?

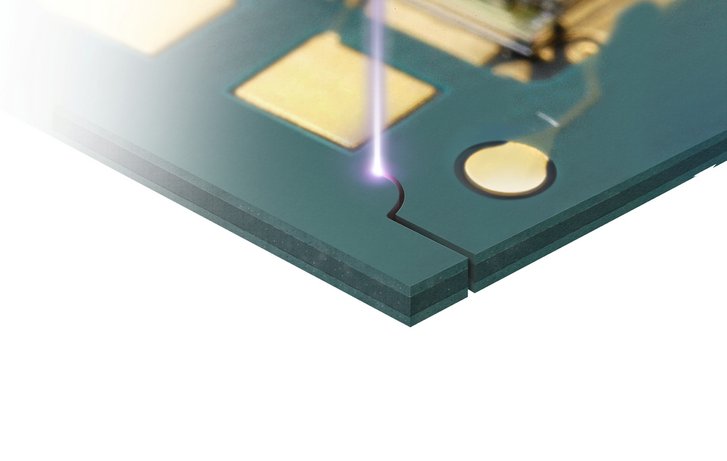

Laser Depaneling is one of the most innovative processes to separate printed circuit boards (PCBs) out of the panel. With traditional depaneling methods, assembled PCBs are cut out of the panel using a mechanical separation process. In the case of Laser Depaneling, the depanelization process is performed using a focused laser beam that ablates the material layer by layer. The laser process - especially in case of LPKF machines - offers considerable advantages over conventional mechanical cutting processes.

Overview of processes for depaneling

In addition to laser depaneling, there are several other methods for separating PCBs. The processes differ in terms of cost, reliability and quality levels. These processes include, among others:

Comparison of Laser Depaneling with mechanical separation processes

Benefits of Laser Depaneling

The narrow beam diameter of the laser enables precise and high quality processing of the material. In addition, the fusion of the materials at the cutting edge prevents fraying and ensures a closed edge of the component.

LPKF's innovative CleanCut-technology also ensures unprecedented technical cleanliness of the processed material (100% carbonization-free).

In mechanical processes, such as milling, dust is generated during the manufacturing process. Laser depaneling, on the other hand, evaporates the material. In this case, the resulting fumes are disposed of with the use of an extraction system. Potential malfunctions due to deposited dust are thus avoided.

With Laser Depaneling, a wide variery of different substrate materials can be processed with ease by varying the process parameters. Additional and/or proprietary tools are not necessary for the processing of different materials.

New applications, such as in the high-frequency range, require the development and processing of special materials that must meet specific requirements. These sensitive and demanding materials can only be processed to a limited extent using classical mechanical processes. In these application contexts, Laser Depaneling is the predestined solution.

In contrast to mechanical processes for depaneling, there are virtually no limits to the design freedom of PCBs in Laser Depaneling. Due to the flexible lines and the narrow diameter of the laser beam, even very fine and complex structures can be implemented without any problems. The fine laser further ensures that the distances between the cutting edges and the components are minimized and that the maximum permissible height of the assembly is maximized.

It is not necessary to consider minimum radii or ridge widths, as in the case with milling, for example.

In addition to cutting, the laser offers a wide range of other applications: drilling, marking or structuring can also be carried out with the aid of the laser. For example, the laser system can be used to produce coverlayers which is an increasingly important application that is growing more and more common each day.

Misconceptions about Laser Depaneling

The initial investment in Laser Depaneling systems is comparable to that of standard routing machines on the market today, however due to the elemination of consumable tooling costs for router bits or saw blades, operational running costs of a laser depaneling system are significantly lower.

Further information on a cost analysis of laser depaneling can be found here.

In the case of laser systems, there is a common misconception that the printed circuit board or components could be damaged by laser-induced heat. This false assumption is based on obsolete 30+ year old laser technology and is simply not the case today. At just 100 µm from the point of impact temperatures only reach a maximum of 65°C - only about half as high as the reflow process previously carried out during assembly. As a result, damage to components or the PCB is far more likely to occur during the reflow process, but not during laser depaneling.

Unique selling propositions of Laser Depaneling by LPKF

With its innovative solutions and machines for Laser Depaneling, LPKF offers its customers a number of unique selling propositions (USPs). These guarantee a maximum of efficiency and quality across the competitive landscape.

Material savings through full cut:

The LPKF laser machines have achieved a price/performance ratio that makes it possible to cut the full perimeter of printed circuit boards instead of just cutting the break-out tabs. When laser machines from LPKF are used for depaneling, savings of more than 30% of board material can be achieved by cutting the full perimeter of the board outline. This eliminates the need for pre-routing prior to assembly. By eliminating all of the 2-3 mm wide pre-routing channels around each individual PCB, more boards can be squeezed on to each panel. More boards per panel means less panels to build, further reducing material and operational costs.

CleanCut-Technology:

The CleanCut-technology specifically developed by LPKF prevents the formation of soot which has often occured in the past during laser processing. In this way, an unprecedentec technical purity of the printed circuit boards is guaranteed. The material examined after the process is 100% carbonisation-free!

Risks of potential malfunctions of the PCBs or the attached components are reduced to a minimum by using the CleanCut-technology.

Market leadership:

LPKF is the market leader in the field of Laser Depaneling and has already imlemented several hundred systems in the field. The increasing customer requirements and changing technological boundary conditions are therefore well known and are taken into consideration as part of continous further developments and new developments of systems.

The suitability and quality of systems are also proven by numerous applications in the automotive, consumer electronics and medical technology sectors.